‘Munkhiin Tun’ LLC produces 45 thousand masks daily

Economy

Ulaanbaatar /MONTSAME/. The World Health Organization recommends regular usage of face masks in order to take preventive measures against the ‘COVID-19’ novel coronavirus that is transmitted through droplets in the air. Countries are having factories work at its full capacity to meet their domestic demand for face masks. During this difficult time, the only face mask factory in the country is operating 24/7, providing 45 thousand face masks each day.

Face mask production increased by 10 times

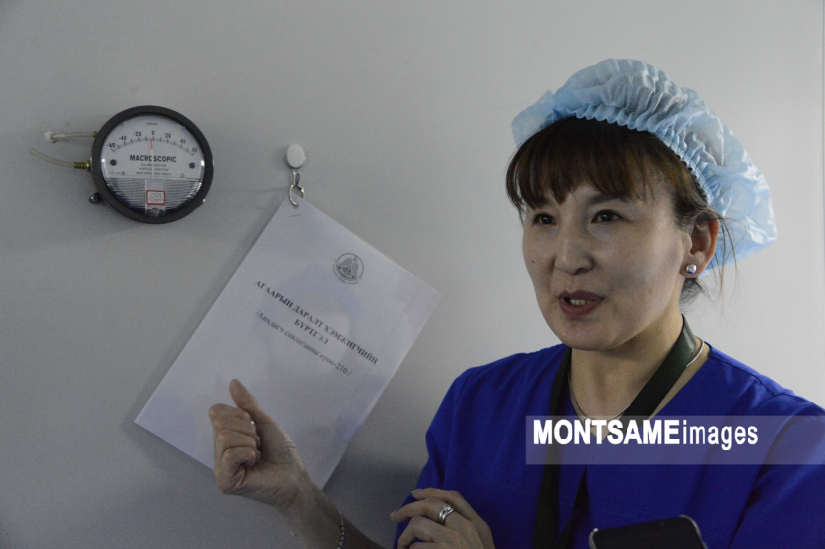

No one enters this business because face mask production gives no profits. However, it is exactly during emergencies like this that it serves as a guarantee for the national security by providing for the domestic demand to a certain extent, highlighted General Director of ‘Munkhiin Tun’ LLC Ts.Altantsetseg.

In normal times, the factory produces about 100 types of products. However, today they have temporarily halted all other products aside from face masks and protective gear that are of high need in Mongolia, putting its over 200 workers to work at full capacity. Prior to the COVID-19 infection, the factory produced about 500-600 thousand face masks annually. Compared to the daily amount of 2,000 face masks, and at times 7,000 face masks maximum, the face mask production of the factory has increased by 10 times from the average.

Reserves to produce 8 million face masks are available

Mongolia has imported 4.4 million face masks this year so far. Today, imported face masks are being sold at MNT 1,200-3,500 in pharmacies. As for domestically produced face masks with 95 percent capacity to protect from viruses, it is being sold two times cheaper for MNT 700. The reason why the cheaper, yet good quality face masks are not able to be provided to citizens is due to the insufficient monitoring of price gouging. “Previously, we put our face masks on the market. However, individuals bought the face masks in large quantities and began to sell them at prices that were many times higher. Thus, we came to the decision to provide face masks per requests from organizations,” explained Chairman of ‘Munkhiin Tun’ LLC D.Batkhishig.

This year, the factory has provided face masks to about 280 hospitals and organizations aside from the Ministry of Health. And the currently available materials in the factory’s storage, as well as additional materials being imported, makes it possible to produce 8 million face masks, 150 thousand protective gears, and 120 thousand surgical gowns.

Single use protective gear being produced 4 times cheaper domestically

Protective gear that is used by officials working on the frontline of fight against infections is being produced for the very first time in Mongolia. The gear that is sold for USD 19 in China, USD 40 in South Korea, and USD 50 in the U.S. is being sold for MNT 25,000--at a price that is 4 times cheaper, highlighted Chairman of ‘Munkhiin Tun’ LLC D.Batkhishig.

The company’s ‘Tun Pharm’ medical factory has registered 47 medicines of 5 types in the state registry of medicine of Mongolia. With the introduction of the international GMP standard in the factory, it has also become possible to export its medicinal products internationally.

“One of the most crucial equipment for the GMP standard is the ventilation system. In order to prevent contamination during the process of manufacturing medicine, the pressure of each room has to be different by 5-10 pascals. This prevents one type of medicine from contaminating the other,” explained Director of ‘Tun Pharm’ factory M.Khad-Erdene.

The water used in medicine production goes through 7 filters, and it is also used in decontamination and cleaning of the factory. The single-use protective gear is disinfected with ethylene oxide for 10 hours. As a result, the cleanliness of the product is kept for 5 years.

Ulaanbaatar

Ulaanbaatar